Marble laser engraving is a modern technique that allows you to etch designs, text, and artwork onto marble surfaces with unmatched precision and detail. Unlike traditional engraving methods, which can be time-consuming and labor-intensive, lasers offer a clean, efficient, and highly customizable approach.

In this guide, we’ll explore how laser engraving works on marble, the machines used, and why lasers are the ideal tool for creating beautiful, lasting designs.

In this article:

Part 1: The Overview of Marble Laser Engraving

1.1 What is Marble Laser Engraving?

Marble laser engraving is a cutting-edge method for etching designs, text, and artwork onto marble surfaces with exceptional precision, fine detail, or even a a 3d embossing effect on stone

1.2 How Does Laser Engraving Work on Marble?

Laser engraving works by removing a thin layer of the marble surface through thermal ablation. The laser’s high-energy beam heats the marble, causing it to micro-fracture and vaporize the surface layer, leaving a permanent mark. This process does not rely on chemical reactions, making it suitable for natural stone while maintaining its durability.

Since the laser beam is controlled by computer software, even intricate and complex designs can be engraved with high accuracy.

1.3 Marble Engraver Machine/Tool

To laser engrave marble, you'll require a laser engraver, which is crucial for streamlining the engraving process and achieving precise results. With various laser engraving machines on the market (like Diode laser engraver, CO2 laser engraver and Fiber laser engraver), many may ask: "Which laser is best for marble laser engraving?" or "What tools do I need to engrave marble?"

Actually, it depends on your engraving needs. For home or small-scale marble laser engraving project, diode laser engraver like LP5 is the good choice. Because these marble laser engraving machines are easy to use and budget-friendly.

What Makes Lasers Great for Engraving Marble?

Laser engraving offers several advantages over traditional engraving methods, making it an excellent choice for marble projects.

① Precision and Detail

Lasers can create fine lines, intricate patterns, and even photo-realistic images that are difficult or impossible with manual tools. The computer-controlled movement ensures consistent accuracy across the entire surface.

② Speed and Efficiency

Compared to chiseling or sandblasting, laser engraving is much faster. Complex designs that might take hours by hand can be completed in minutes, making it ideal for both personal projects and commercial production.

③ Non-Contact and Minimal Damage

Since the laser does not physically touch the marble, there is minimal risk of cracking or chipping the stone. This non-contact process preserves the integrity of the marble while producing clean, precise marks.

④ Versatility

Lasers can engrave different types and colors of marble and can be programmed for a wide range of designs. Whether it’s text, logos, or intricate artwork, lasers can handle it efficiently.

⑤ Repeatability

Once a design is programmed, it can be replicated perfectly multiple times. This is particularly valuable for batch production of memorials, tiles, awards, or decorative items.

💡 Case Study: Laser Engrave Marble Cube within 5 Steps

Preparation checklist for laser engraving marble:

- Engraving Material: Marble Cube

- Engraving Machine: Diode Laser Engraver

- Engraving Design: Name, Logo, Images, Patterns, etc.

Can you laser engrave marble? Yes! The process is straightforward. So, How long does it take to engrave marble? Don't worry, just follow these 5 simple steps to get your laser engraved marble crafts in a few hours!

Step 1: Choose Your Material - Marble Cube

Selecting the right material is crucial to get the customized marble. Different materials require specific laser settings to ensure precise engraving. In this guide, we'll conduct a case study of engraving zeus portrait on a marble cube.

Step 2: Choose the Right Laser Engraving Machine for Marble Engraving

Here, we recommend LaserPecker 5 (LP5), which comes with a 20W 450nm diode laser and a speed of up to 10,000 mm/s, delivering excellent performance for marble engraving.

Step 3: Prepare Your Cutting Design

Use a LaserPecker graphic design app/software or third-party graphic design tools like photoshop to create or import the shape or design you want to engrave on the marble's surface. Consider size, shape, and other details.

*You can also visit LaserPecker CraftZone for inspiration or to purchase files online.

Step 4: Set up the Marble Laser Engraving Machine

Firstly, Make sure your engraver is powered on, and then connect your laser engraver to your computer or mobile device using the appropriate interface (WiFi, USB, Bluetooth, etc.)

Secondly, Open the LaserPecker Design Space and load your design. (formats like JPG/PNG/G-Code/SVG etc are all acceptable)

Source File: LaserPecker CraftZone

Thirdly, place the items in the designated working area, turn on Preview Mode, and make sure the laser is properly focused.

Fourthly, check if your design fits properly on the marble surface. If not, adjust its size and position to match the material's dimensions.

Finally, Access the software's laser settings to adjust parameters like power, speed, and resolution according to the marble's properties and design intricacy. You might be wondering, "How much laser power is needed to engrave marble?" Rest assured, I've got you covered!

To get the best result, the recommended laserpecker LP5 material settings for engraving marble is 20 W 1064 nm Diode Laser; Resolution: 4k; Power: 100%; Depth: 20%; Mode: 3D Grayscale Embossing

When operating a laser engraving machine, it's advisable to wear goggles or use a laser protection cover to protect your eyes and body from potential harm, as the blue laser can pose risks.

Additionally, please be mindful that smoke or toxic gases may be emitted during the laser engraving process. Wearing a mask or employing an air purifier is essential for safety.

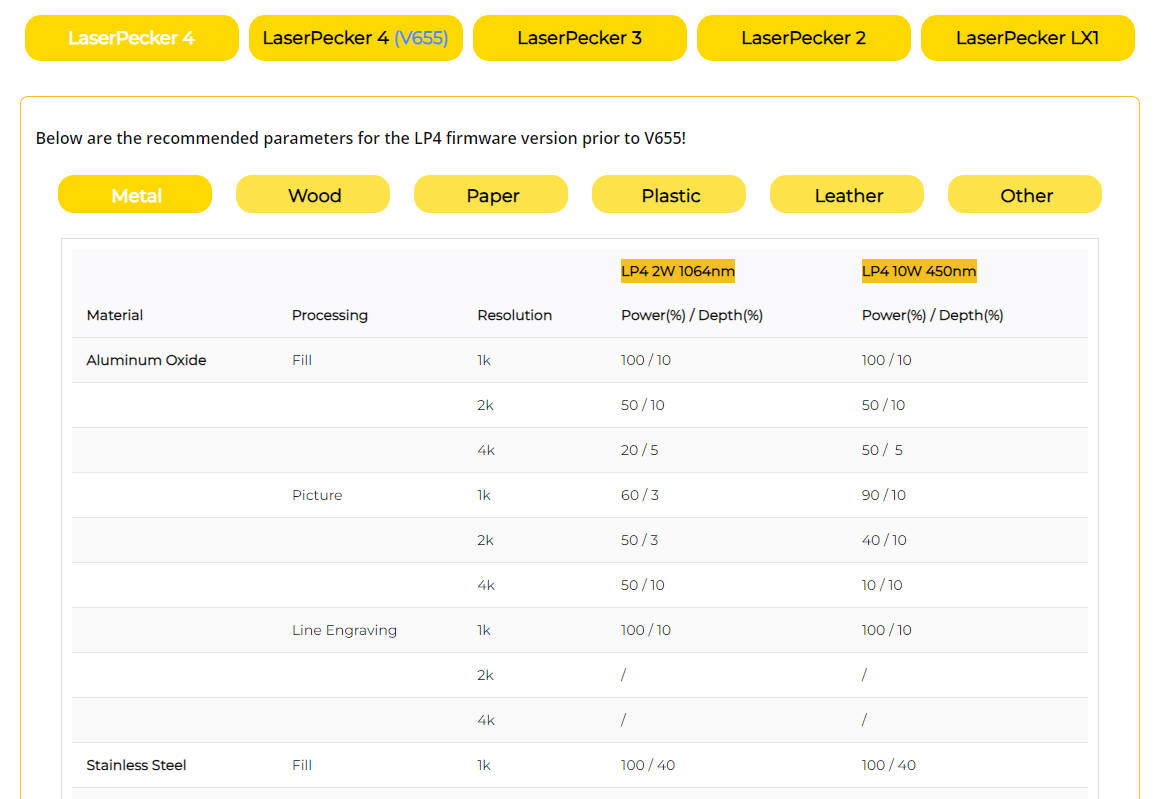

To explore other recommended laserpecker engraving and cutting parameters, refer to the settings table that applies to any laserpecker machines, including LP1, LP2, LP3, LP4 and LP5.

Step 5: Start Engraving Your Marble With Laser Now

Double-check everything to avoid mistakes. Then, hit the start button and watch the magic happen. The laser brings your design to life. Keep an eye on it, and you're all set!

Conclusion

Laser engraving has revolutionized how marble can be customized, combining speed, accuracy, and versatility in a single process. Whether you’re creating decorative pieces, personalized gifts, or portrait, understanding how the technology works and using the right machine ensures clean, precise, and repeatable results. With the right tools and techniques, anyone—from beginners to experienced artisans—can unlock the full potential of marble laser engraving.