Aluminum sheets are great. They're light, strong, and don't rust, so they're used everywhere from factories to DIY projects. To get a nice, clean cut, you just need to know how.

This article talks about some common ways to cut aluminum sheet, and why lasers are usually the best way to go. Plus, I’ll walk you through the simple steps of laser cutting, share some tips from the pros, and even suggest some machines.

In this article:

- Part 1: Why Cutting Aluminum Sheet is Challenging

- Part 2: Overview of Aluminum Sheet Cutting Methods

- Part 3: How to Cut Aluminum Sheet with a Laser Machine (Step-by-Step)

- Part 4: Tips for Perfect Aluminum Sheet Laser Cutting

- Part 5: Recommended Laser Cutting Machines for Aluminum

- Part 6: FAQs about Cutting Aluminum Sheet with a Laser

Part 1: Why Cutting Aluminum Sheet is Challenging

Aluminum seems like it would be easier to cut than steel since it's softer and lighter. But cutting aluminum has its own set of issues:

1. Heat

Aluminum moves heat very well. When you cut it, the friction makes heat that the metal takes in and spreads fast. This can make the sheet bend, especially if it's thin. The heat can also hurt the blade.

2. Softness

Even though aluminum is strong, it's also soft, which makes cutting it tricky. The material can get sticky, which creates friction and heat. This can make the cut rough. Also, it's easy for rough edges to form, and you'll have to file them off.

3. Hardening

Cutting can change the aluminum. When the metal gets stressed by the heat and friction from the blade, it gets harder. The area around the cut gets stronger but also easier to break. This can make it harder to cut again and make the result less even.

4. Thickness

Aluminum sheets come in all sorts of sizes, thin or thick. You can't just use one cutting method for everything. What slices through a thin sheet might be useless on a thick one. Plus, some aluminum is hard, some is soft – that all changes how you gotta cut it.

So, you gotta pick the right cutting method and tools if you want a clean cut. Mess it up, and you could end up wrecking both the aluminum and your tools.

Part 2: Overview of Aluminum Sheet Cutting Methods

You can cut aluminum sheets in a few ways, from using simple hand tools to using fancy CNC machines. Let's check out some common methods, with what's good and not so good about each.

| Cutting Method | Pros | Cons | Best for |

|---|---|---|---|

| Hand Tools (Snips, Saws) | Low cost, accessible, no power needed | Slow, labour-intensive, rough edges | DIY projects, thin sheets (<2mm) |

| Shearing | Fast, clean, straight cuts, no heat | Limited to straight cuts, not versatile | Industrial straight-line cutting |

| Jigsaw/Bandsaw | Can cut curves, affordable | Rough finish, risk of blade clogging | Small workshops, medium sheets |

| CNC Milling | High precision, repeatable cuts | Expensive, slower, requires expertise | Complex shapes, prototypes |

| Plasma Cutting | Cuts thicker aluminum, relatively fast | Less precise, generates rough edges | Heavy-duty metal fabrication |

| Waterjet Cutting | Extremely precise, no heat distortion | Very costly, large machine footprint | Aerospace, industrial uses |

| Laser Cutting | Ultra-precise, clean edges, flexible | Requires investment, thickness limits | High-quality, detailed cutting |

Laser cutting provides the best mix of accuracy, clean cuts, and many uses, says this table. It's a solid choice if you're a maker, designer, or manufacturer looking for exact cuts and little cleanup.

Part 3: How to Cut Aluminum Sheet with a Laser Machine (Step-by-Step)

Laser cutting aluminum is pretty easy once you get the hang of it. Here’s a simple step-by-step to get you started:

1. Prep Your Design

Use graphic design software (like LaserPecker Design Space, or LightBurn) to make or upload your design. Then save it as a laser-friendly file, like DXF, SVG, or AI.

2. Pick the Right Laser

A fibre laser cutter works best for metals like aluminum. Diode lasers can handle thin stuff. Your machine should have enough power (at least a 20W fibre laser for thin aluminum).

3. Hold the Aluminum Down

Put the aluminum sheet on the laser bed and clamp it down or use magnets so it doesn’t move. Keep it flat for clean cuts.

4. Adjust the Laser

Set the power, speed, and frequency based on how thick the aluminum is. For thin aluminum (under 1mm), try lower power and higher speed. After that, test your settings on some scrap aluminum first.

5. Cut Away!

Now you can start cutting. Watch out for flames, sparks, or bending.

6. Finishing Up

Check the edges for rough spots. Sand them down if needed. Don’t forget to clean off any residue from the surface.

Part 4: Tips for Perfect Aluminum Sheet Laser Cutting

Want to get awesome laser cuts, even with a really good machine? Here's some simple advice to make your aluminum cuts look their best:

Gas Assist is Your Friend

Using oxygen or nitrogen helps blow away the melted bits. This means less mess and cleaner edges.

Clean Your Lenses

A dirty laser lens can screw things up. Keep it clean for the best accuracy.

Stay Cool

Aluminum loves to spread heat. Make sure your machine's cooling system is doing its job.

Test It Out

Don't ruin your good stuff! Try cutting some scrap pieces first to dial in your settings.

Think About Thickness

Regular lasers are fine for aluminum up to 1mm thick. Got thicker sheets? You'll need a more powerful, industrial laser.

Stay Safe

Always wear safety glasses. Keep the air moving, and watch the machine while it's working.

Part 5: Recommended Laser Cutting Machines for Aluminum

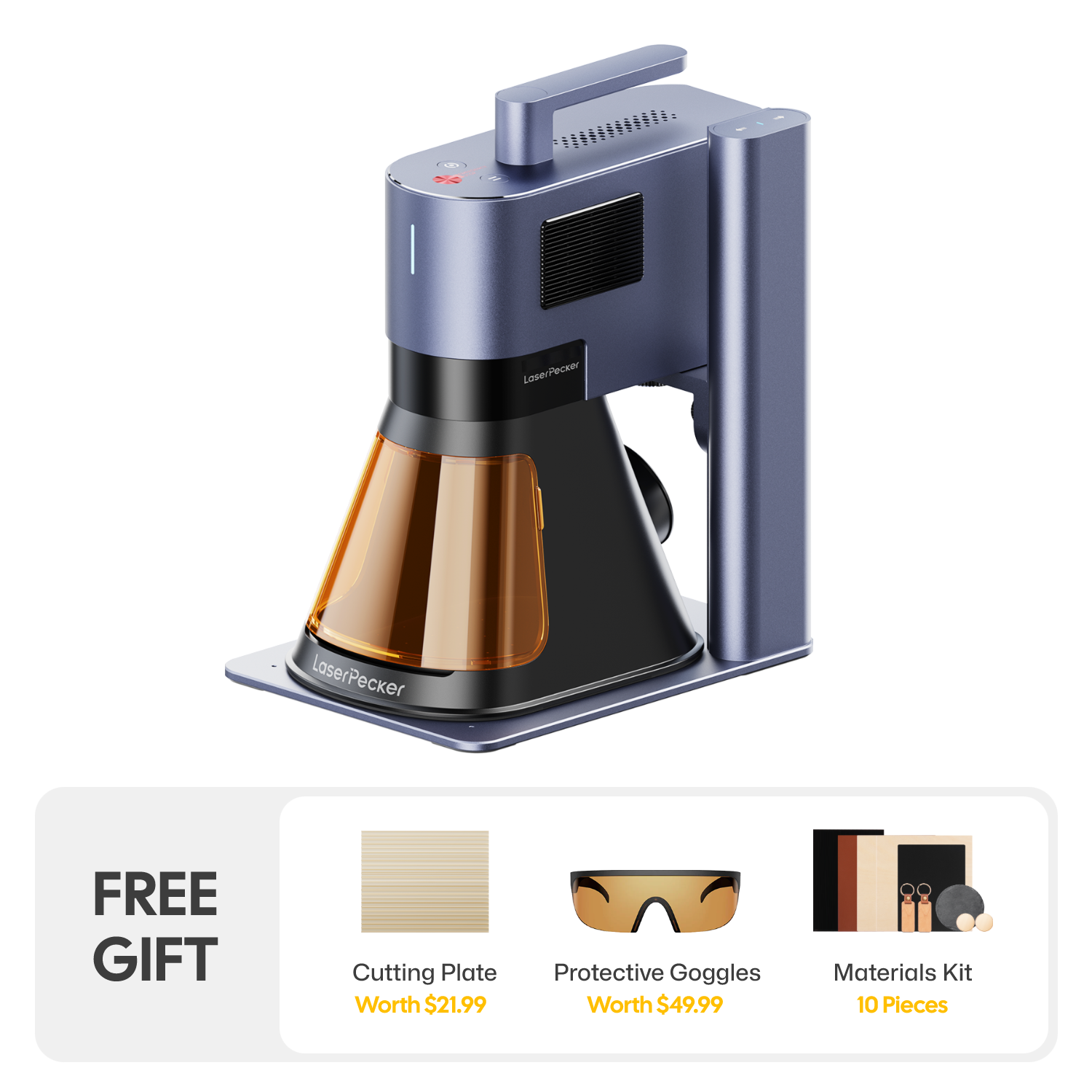

If you're serious about cutting aluminum, getting a good laser cutter is key. A top choice right now is the LP5 Laser Cutter. It is a machine designed to be the most capable, lightest, and most compact engraver in its class. It's not just a powerful tool; it’s a versatile and reliable solution for a wide range of materials and applications.

The LP5 stands out with its innovative dual-laser technology:

20W Fiber Laser (1064nm): This is your go-to for cutting and engraving metals. It’s perfect for slicing through thin sheets of aluminum, stainless steel, brass, and titanium.

20W Diode Laser (450nm): This laser is ideal for non-metal materials like wood, acrylic, leather, and more, giving you the flexibility to tackle almost any project.

What LP5 Can Do

Engraving: Use the fiber laser for bare and coated metals, plastics, and leather, or switch to the diode laser for materials like lacquered metal, wood, and more.

Cutting: The fiber laser can slice through aluminum, brass, stainless steel, and titanium sheets up to 1mm thick. The diode laser can cut dark acrylic up to 15mm and basswood up to 20mm.

In addition to its dual-laser system, the LP5 is packed with features that enhance its performance and ease of use:

Main Things to Know

- Small, Light, and Strong: Easy to move around but still packs power.

- Fast: Engraves at speeds up to 10,000mm/s.

- Cuts Deep: Makes detailed 3D designs and clean cuts.

- Do More with Add-ons: Use slide or rotary tools for big or round projects.

- Easy to Use with Software: Works with LightBurn and LaserPecker Design Space.

- Safe to Use Inside: With its safety enclosure, it’s safe for shops and classrooms.

For a machine that can do a lot, is strong, and easy to carry, the LP5 is a great pick for cutting aluminum and other stuff.

Part 6: FAQs about Cutting Aluminum Sheet with a Laser

1. Can I use just any laser cutter on aluminum?

Not exactly. When it comes to aluminum, lasers aren't all the same. Diode lasers? They're okay for marking aluminum if it's got a coating, since they can change the surface colour, but if you actually want to cut or make deep marks in the metal itself, you're going to want a fibre laser.

Fibre lasers focus power into a tiny spot, which melts the metal away. For those of you doing this as a hobby, think about grabbing a diode+fiber setup. You can switch to the diode for other stuff, and then use the fibre for cutting thin metal or making marks that will last.

2. What's the thickest aluminum a laser can slice through?

How thick you can cut depends on the laser's power and lenses. Smaller fibre lasers are usually fine with thin sheets, around 0.5–1.0 mm. But stronger lasers with good gas can get through even more.

3. Do I need gas when I laser cut aluminum?

Yes, gas makes metal cutting better. Oxygen can speed up the process by reacting with the metal, but it might stain the edges. Nitrogen stops that staining, so edges look clean. For simple stuff, using compressed air could work okay for rough cuts. Though if you want the surface to look professional, use nitrogen.

4. Is laser cutting aluminum safe?

Laser cutting can be safe if you do it right. Metals bounce the laser, so use machines ready for metal cutting and make sure you have safety in place. Always have lots of air moving where you work, since cutting some stuff makes bad smoke. Wear the right safety stuff. Also, the machine should be closed when it's running, and the emergency stops need to work. Machines that are enclosed lower risk, so they're good choices for schools or stores.

5. Why pick laser cutting over plasma or waterjet?

All methods have their benefits. Plasma is quick and not overpriced for cutting thick metals, but get ready for rough edges. Waterjet doesn't use heat and can slice through seriously thick materials, but the machines are big and keeping them running costs a lot. Laser cutting is nice for thin to medium metals and for details. Expect a fine cut, no worn-out tools, and very fine details. It is a great choice for signs, precise parts, and decorations.

Conclusion

In conclusion, cutting aluminum sheets can be tricky because it's soft and conducts heat, plus it tends to create those annoying burrs. But don't worry, with the right way, you can get great cuts. Sawing and shearing work sometimes, but laser cutting is usually the most exact and best way to go.

If you're just starting, the LP1 Pro is a cheap and easy-to-carry option to try laser engraving. If you're running a business, the LP4 is faster, works with all sorts of materials, and gets the job done just right.

With a good machine like the LP5, you can cut and mark aluminum sheets with great exactness. It works if you are just doing your own thing or making a bunch of stuff.