Clothing has always been a way to express personality, creativity, and style. While traditional methods like embroidery, printing, or sewing have long been used to customize apparel, laser engraving is quickly emerging as a modern, precise, and versatile alternative. From fashion brands adding unique patterns to hobbyists personalizing jackets, jeans, or leatherwear, this technique opens up endless creative opportunities.

In this guide, we’ll walk you through the basics of clothing laser engraving — what it is, how it works, the machines you’ll need, and the safety precautions to follow. We’ll also explore why this method is becoming so popular and provide a simple step-by-step process so beginners can get started with confidence.

In this article:

- Part 1: The Overview of Clothing Laser Engraving

- 1.1 What is Clothing Laser Engraving?

- 1.2 How Does Laser Engraving Work on Clothing?

- 1.3 What Engraving Machine Works Best for Clothing Engraving?

- 1.4 Safety Precautions Before Engraving Clothing

- Part 2: Why Use Laser Engraving for Clothing?

- Case Study: How to Laser Engrave Clothing in 5 Steps💡

Part 1: The Overview of Clothing Laser Engraving

1.1 What is Clothing Laser Engraving?

Clothing laser engraving is a modern technique that uses a concentrated laser beam to etch or mark designs directly onto fabric. Unlike traditional printing or embroidery, laser engraving doesn’t require inks, threads, or physical contact. Instead, the laser removes or alters the top layer of the material to create permanent patterns, logos, or textures. It’s widely used in fashion, sportswear, denim, and even leather goods for adding creative designs or brand details.

1.2 How Does Laser Engraving Work on Clothing?

The process works by directing a focused laser beam onto the fabric surface. Depending on the type of material, the laser either changes the color of the fibers, burns away a thin layer, or creates a textured effect.

For example, on denim, the laser can lighten the surface to mimic a “washed” effect, while on leather it can produce deep, sharp engravings. By adjusting the power, speed, and focus of the laser, designers can achieve anything from subtle patterns to bold, high-contrast designs.

1.3 What Engraving Machine Works Best for Clothing Engraving?

The most commonly used machines for clothing engraving are diode laser engravers, since they work well with organic materials like cotton, denim, and leather.

For home or small-scale cloth laser engraving project, diode laser engraver like LP5, LP4 or even LP2 are the good choice. Because these cloth laser engraving machines are easy to use and budget-friendly.

1.4 Safety Precautions Before Engraving Clothing

Safety is essential when working with lasers and fabrics.

- Proper Ventilation: Always ensure proper ventilation, as some fabrics (especially synthetics) can release fumes when engraved.

- Material Check: Test a small sample of the fabric first—some materials may discolor or burn unexpectedly.

- Fire Safety: Keep a fire extinguisher nearby, as fabrics are flammable if exposed to too much heat.

Part 2: Why Use Laser Engraving for Clothing?

Laser engraving has become a go-to method in the fashion and apparel industry because it combines creativity, efficiency, and durability. Unlike traditional decoration methods, it offers unique advantages that make it stand out.

① Precision and Detail

Laser engraving allows for extremely fine details that are hard to achieve with embroidery or printing. From intricate logos to delicate patterns, the laser can reproduce sharp lines and textures with consistent quality.

② Durability

Because the design is engraved directly into the fabric’s surface, it doesn’t peel, crack, or fade like screen printing or heat transfers might. This makes it ideal for clothing that will be washed and worn frequently, such as sportswear, denim, or uniforms.

③ Versatility Across Materials

Lasers can be used on a wide range of fabrics—denim, cotton, polyester, leather, and even blends. Designers can achieve different effects depending on the fabric, such as faded textures on jeans or crisp engravings on leather jackets.

④ Speed and Efficiency

Once a design is uploaded to the machine, engraving is fast and repeatable. This makes it suitable for both one-off custom pieces and bulk production runs without sacrificing quality.

Case Study: How to Laser Engrave Clothing in 5 Steps💡

Preparation checklist for laser engraving clothing:

- Engraving Material: Clothing

- Engraving Machine: Diode Laser Engraver

- Engraving Design: Name, Logo, Images, Patterns, etc.

Can you engrave clothing? Yes! The process is straightforward. So, How long does it take to engrave clothing? Don't worry, just follow these 5 simple steps to get your laser engraved clothing in a few minutes!

Step 1: Prepare Your Design

Start with the artwork, logo, or text you want to engrave. Use vector files (like SVG or AI) for the cleanest results, though most engraving software also supports images and text. Keep in mind that fine lines and high-contrast designs work best on anodized aluminum.

Step 2: Choose the Right Laser Engraving Machine for Clothing Engraving

Here, we recommend LaserPecker 4 (LP4), which comes with a 10W 450nm diode laser, 2W 1064nm IR laser and a speed of up to 4,000 mm/s, delivering excellent performance for clothing engraving.

Step 3: Secure the Fabric

Place the clothing item flat on the engraving bed, ensuring there are no wrinkles. Use weights, tape, or clamps if needed to prevent movement. A stable, flat surface is crucial for consistent engraving depth and precision.

Step 4: Set up the Clothing Laser Engraving Machine

Use a LaserPecker graphic design app/software or third-party graphic design tools like photoshop to create or import the shape or design you want to engrave on the clothing's surface. Consider size, shape, and other details.

*You can also visit LaserPecker CraftZone for inspiration or to purchase files online.

Now, it's time to set the laser engraving machine parameters.

Firstly, Make sure your engraver is powered on, and then connect your laser engraver to your computer or mobile device using the appropriate interface (WiFi, USB, Bluetooth, etc.)

Secondly, Open the LaserPecker Design Space and load your design. (formats like JPG/PNG/G-Code/SVG etc are all acceptable)

Thirdly, place the items in the designated working area, turn on Preview Mode, and make sure the laser is properly focused.

Fourthly, check if your design fits properly on the clothing surface. If not, adjust its size and position to match the material's dimensions.

Finally, Access the software's laser settings to adjust parameters like power, speed, and resolution according to the clothing's properties and design intricacy. You might be wondering, "How much laser power is needed to engrave clothing?" Rest assured, I've got you covered!

To get the best result, the recommended laserpecker LP5 material settings for engraving clothing is 10 W 450nm Diode Laser; Resolution: 4k; Power: 40%; Depth: 40%; Pass: 1.

When operating a laser engraving machine, it's advisable to wear goggles or use a laser protection cover to protect your eyes and body from potential harm, as the laser can pose risks.

Additionally, please be mindful that smoke or toxic gases may be emitted during the laser engraving process. Wearing a mask or employing an air purifier is essential for safety.

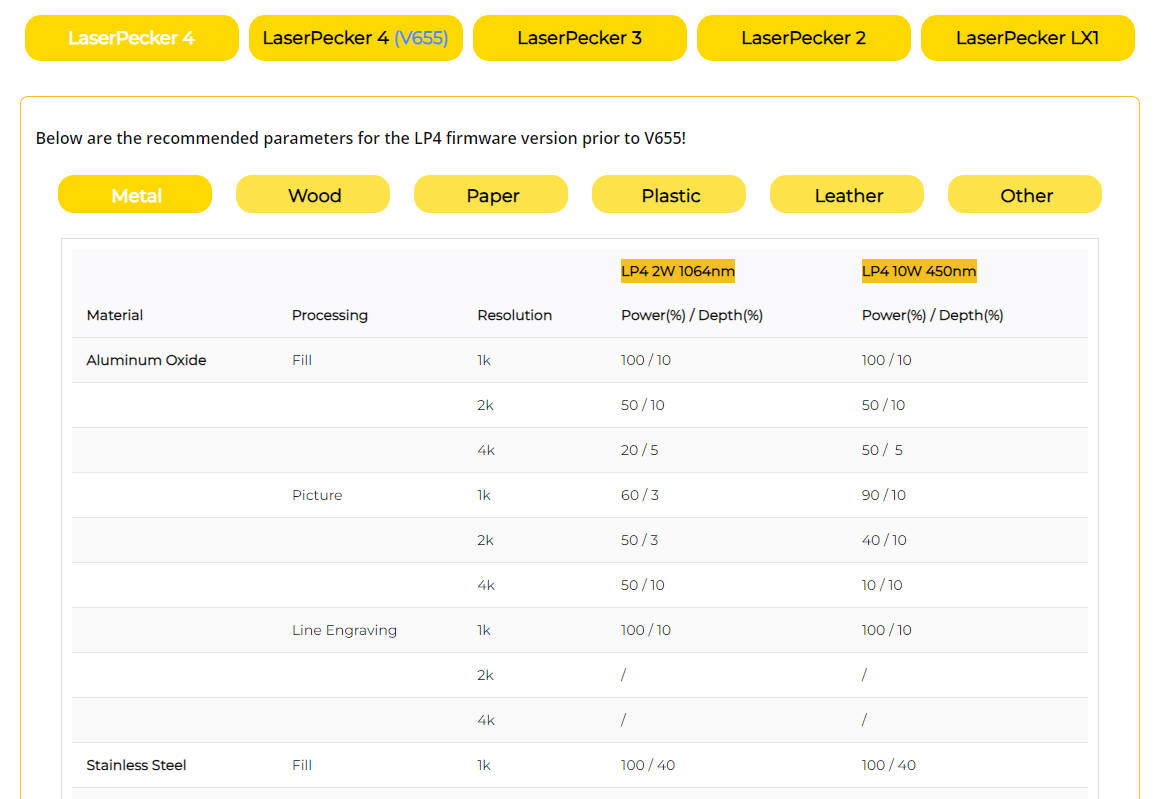

To explore other recommended laserpecker engraving and cutting parameters, refer to the settings table that applies to any laserpecker machines, including LP1, LP2, LP3, LP4 and LP5.

Step 5: Start Engraving Your Clothing With Laser Now

Double-check everything to avoid mistakes. Then, hit the start button and watch the magic happen. The laser brings your design to life. Keep an eye on it, and you're all set!

After engraving, carefully remove the clothing from the machine. Brush off any residue or fibers, and check the engraved area for clarity and consistency. For denim or leather, a light cleaning with a damp cloth can enhance the final look.

Conclusion

Laser engraving offers a new level of personalization for clothing, blending precision, durability, and creativity into one process. Whether you’re a beginner experimenting with custom T-shirts at home or a small business owner seeking a unique branding tool, this method provides professional-quality results with minimal effort.

By understanding the process, choosing the right machine, and following best practices, you can transform ordinary garments into statement pieces that stand out. With clothing laser engraving, the possibilities for fashion, design, and personal expression are nearly limitless.